The framework will be manufactured through binder jetting (Fig. Send the STL files of the splinted framework and the custom tray to a laboratory for fabrication. Use the tools of the software to make a handle for the custom tray using the "primitive preform" of the software called "cube." Once done, cut and smooth the custom tray to be 3D printed (Fig. Subtract each cylinder from the custom tray, obtaining the holes for unscrewing the impression copings ( Fig. Align them on the same x-, y-, and z-axes as the implant impression copings po- sition (Fig. Create cylinders with the diameter of the impres- sion copings to obtain a single path of insertion for the impression tray with sufficient clearance for the impression copings. 5B) to obtain the custom tray with a thickness of 2 mm (Fig. Once done, use the software tools to subtract one from the other (Fig. 5), and in the other create a 4.5-mm offset. In one STL file, create a 2.5-mm offset (Fig. To fabricate the custom tray, import this STL file twice. Select both STL files and subtract one from the other to obtain the intaglio reproduction of the gingiva in the framework support structure (Fig.

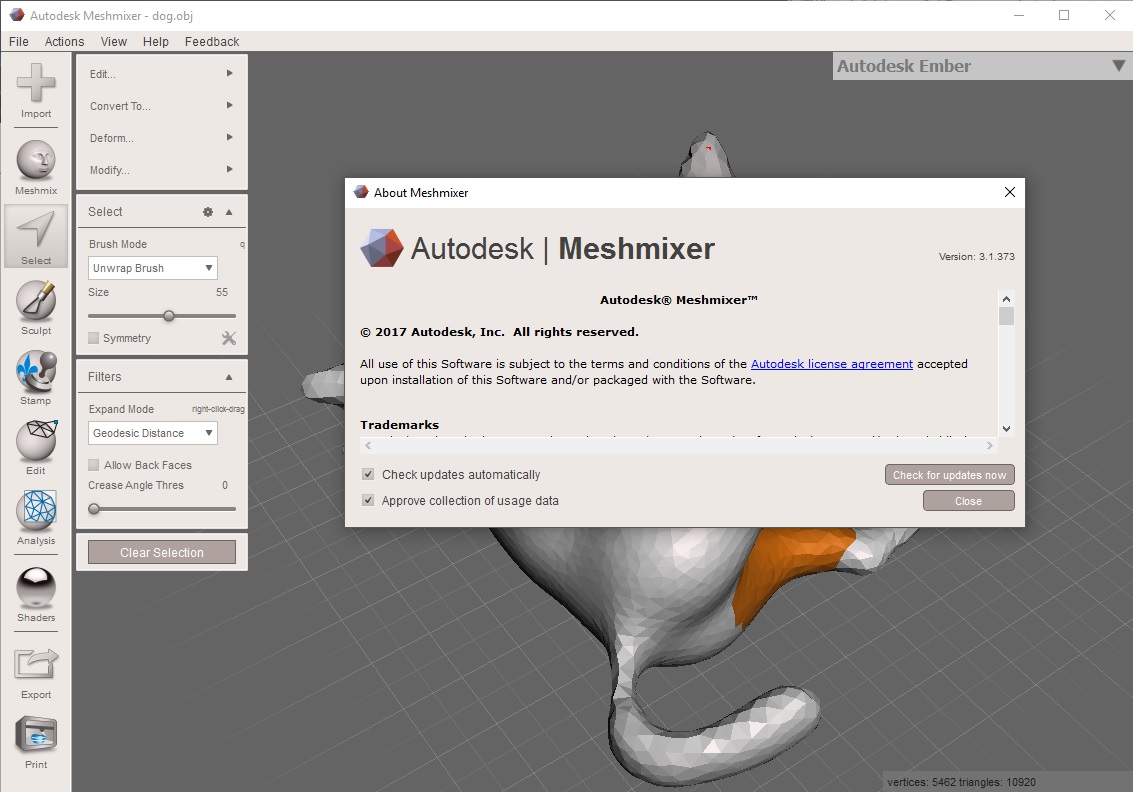

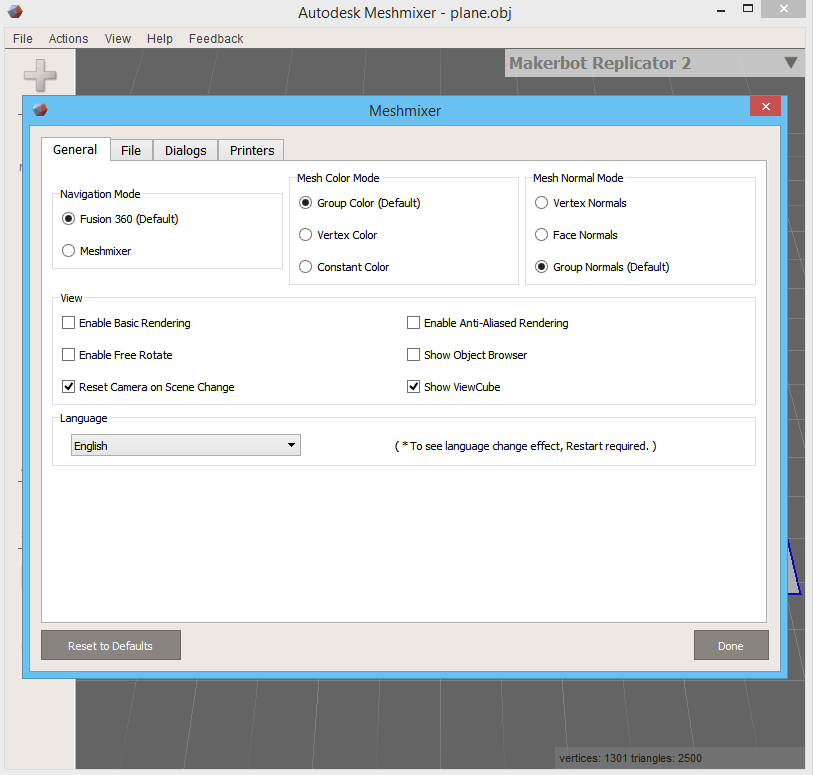

Import the 2 STL files obtained into the CAD soft- ware (Blender, v2.77a The Blender Foundation) (Fig. Finally, export this design as an STL file (Supplemental Video 2). 3C) to serve as support structures in the patient's gingiva. 3B) and select "cube." Then, create 3 structures, 2 posterior and 1 anterior, in the splinting framework by using the "primitive preform" of the software called "cylinder" (Fig. Connect each cylinder to another using the "primitives preforms" tools of the software (Fig. Export the cylinders as an STL file (Fig. The cylinders should have a thickness of 2.5 mm and a height of 4 mm, and a uniform space of 1.5 mm should be left around each impression coping (Fig.

Go to "create" on the menu and use the "cylinder" tool of the software to design cylinders around each impression coping in the optimal 3D position. Import the STL file into open source CAD software (Blender, version 2.77a The Blender Foundation) ( Fig. Replace the healing abutments on each implant.

Alternatively, make an intraoral digital scan (Trios 3Shape) of the impression copings, obtaining the STL file directly. 1B) and digitize the cast with a laboratory scanner (R1000 3Shape) to obtain a stan- dard tessellation language (STL) file of the cast (Fig. Pour it with dental stone Type IV (Fujirock EP GC Corp) according to the manufacturer's in- structions (Fig. Make a preliminary impression with an irreversible hydrocolloid impression material (Hydrogum 5 Zhermack, SpA) in a conventional metal impression tray. impression copings (MIS Implants Technolo- gies Ltd) at a preload of 15 Ncm with a torque wrench (Fig.

0 kommentar(er)

0 kommentar(er)